Leather Cut Out Belt

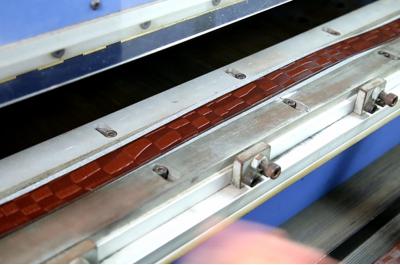

The leather belt is perforated by a laser or die-cutter. Considering the efficiency and cost, a mold will be the first choice to achieve customer requirements. We will use laser cutting to realize sophisticated patterns, which is difficult for traditional mold types. Therefore, whatever hollow effect you want, we can meet your requirements.

Material CharacteristicsGenerally, we use leather as the first choice to make cut out belts. Most leather belts are of single layer because of the heavy weight, different from PU belts requiring a combination of multiple layers. Hence, after perforating the color inside the hole is completely uniform.

We combine cut out craft, embossing technology, and rivet art to implement more abundant and more diverse effects.

Gain Regent is an experienced bespoke leather belt manufacturer specializing in leather processing and belt production since 1982. We have a professional leather belt manufacturing factory and more than 100 dedicated and skilled staff members. We are a team willing to take on a challenge, and we have excellent customizable abilities and rich practical experience to provide fully customized services, including design and production. At present, our products have been sold all around the world, and we have long term cooperation with most luxury brands providing OEM and ODM services.